Introducción del caso

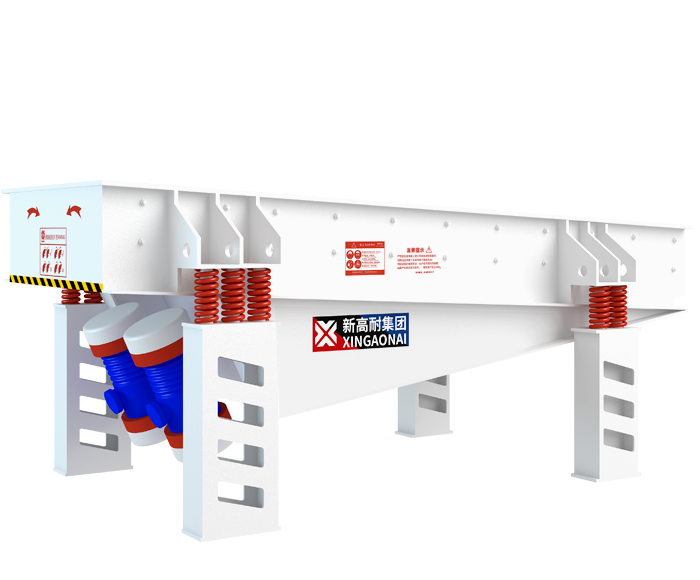

In response to the market demand for high-quality machine-made sand, the customer decided to invest in limestone sand making after multiple investigations, mainly producing machine-made sand below 5 mm for export. At the beginning of purchasing the equipment, the customer compared several mining equipment manufacturers and finally selected Xingaonai Heavy Industry. The project is also equipped with auxiliary equipment such as powder selectors and wet mixers to ensure that the production process meets environmental protection requirements. This sand production line first uses a vibrating feeder to send the material to a single-rotor sand making machine to process it into finished machine-made sand of the specifications required by the customer, and then screens and uses a powder selector to separate and process unnecessary stone powder and valuable finished sand, so as to obtain finished machine-made sand and gravel with relatively scientific and reasonable grading. Finally, the wet mixer is used to humidify the finished sand to avoid dust during material transportation, thereby achieving the purpose of environmentally friendly production.

Áreas de aplicación

Дорожные работы

Расширение автомагистрали

Гражданские здания

Городская инфраструктура

Высокоскоростная железная дорога

Строительство мостов

Железнодорожное строительство

Строительство аэропорта

Configuración relacionada