xgncrusher

xgncrusher

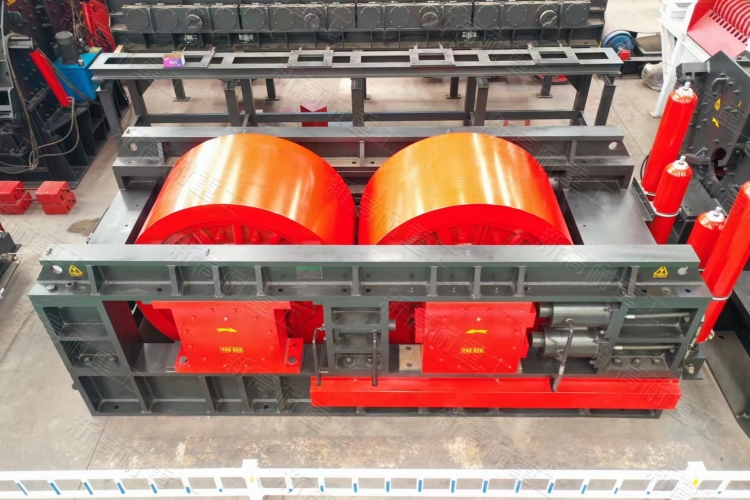

The double-roller sand making machine is especially suitable for crushing raw coal (containing coal gangue) in large coal mines or coal preparation plants. The rollers are important working parts of the double-roller sand making machine. During the crushing process, the two rollers are crushed against each other to crush the materials. Compress into the required particles, so the adjustment of the position and spacing of the two rollers is very critical, which directly affects the intensity of the crushing action and the particle size of the aggregate. Next, let’s briefly talk about the rollers of the double-roller sand making machine. Causes, hazards and adjustment methods of uneven gaps.

reason

Roller offset: When the equipment is running, it is affected by material transportation equipment such as conveyor belts, or is impacted and vibrated, resulting in instability and offset of the roller.

Different degrees of roller wear: Continuous use for too long or improper maintenance results in different degrees of roller wear, resulting in uneven gaps.

Improper installation and adjustment: When installing or adjusting the roller, the operation is improper or not performed in accordance with the specifications, resulting in uneven gaps.

Equipment aging or deformation: As the use time increases, the equipment is prone to roller wear, aging or elastic deformation, resulting in changes in the roller spacing.

Harm

Affects the sand making effect: Uneven roller gaps will cause the material to be subjected to uneven extrusion and shearing forces during the crushing process, resulting in uneven particle size distribution of the crushed material, affecting the sand making effect.

Increase equipment wear: Uneven roller gaps will cause some rollers to bear excessive pressure, accelerate roller wear and shorten the service life of the equipment.

Reduced production efficiency: Uneven roller gaps will cause problems such as material jamming and blocking during the operation of the equipment, affecting the normal operation of the equipment and reducing production efficiency.

Increased energy consumption: Uneven roller gaps will cause the equipment to consume more energy when crushing materials and increase production costs.

Uneven roller gaps will have a negative impact on the crushing efficiency and effect of the sand making machine. Therefore, during use, the roller gaps should be checked regularly to ensure that they are uniform and ensure the normal operation of the equipment and good sand making effects.

method

The smaller the roller gap, the stronger the crushing effect and the finer aggregate particle size produced; the larger the roller gap, the weaker the crushing effect and the coarser aggregate particle size produced. Therefore, in actual use, the roller spacing can be appropriately adjusted according to the characteristics and requirements of the grinding materials to achieve the desired effect. Commonly used methods are as follows:

Wedge device adjustment: The wedge device between the double rollers of the double-roller sand making machine has an adjusting bolt installed on the top. When the adjusting bolt pulls up the wedge, the wedge pushes the movable roller away from the fixed wheel, making the gap between the rollers larger. , the discharge volume becomes larger; when the wedge moves downward, the movable roller approaches the fixed roller under the action of the compression spring, making the gap smaller and the discharge volume smaller.

Gasket device adjustment: Place gaskets of different thicknesses between the frame and the movable bearing, and adjust the size of the discharged particles by increasing or decreasing the number of gaskets or controlling the thickness. When adding gaskets, the gap between the two rollers becomes larger, when the gasket is reduced, the gap between the two rollers becomes smaller and the discharge volume becomes smaller.

Manual adjustment: Open the protective cover of the counter-roller sand making machine, find the counter-roller adjustment mechanism, use a handle or tool to turn the counter-roller adjustment mechanism to the left or right, and adjust the distance between the counter-rollers.

As a large-scale equipment manufacturing company in the mining machinery industry, Xingao Heavy Industry has already formed a complete product series. The company's products cover all aspects of feeding, crushing, sand making, grinding, screening, etc. Crushing equipment not only includes roller sand making machines , as well as heavy hammer crushers, vertical shaft impact crushers, cone crushers, double-rotor sand making machines, etc., which have a high market share. Whether you want to purchase a single piece of equipment or customize an entire production line, we can Can meet your needs!

Superior: No content!

Abajo: No content!

Nuestros productos se han exportado a más de 170 países de África, Asia, América del Sur, Europa, etc. Estamos aquí para ofrecerle mejores productos y servicios.

Copyright © 2024-2030 Xingaonai Group Todos los derechos reservados. Sitemap