xgncrusher

xgncrusher

The performance of concrete is affected by many factors, among which the gradation of machine-made sand is one of the important factors affecting the quality and performance of concrete. According to relevant experimental results, reasonable gradation can improve the workability, strength and durability of concrete. , and poor gradation may lead to a decrease in concrete performance and poor workability of the concrete mixture. Therefore, understanding the impact of manufactured sand grade on concrete properties is of great significance for optimizing concrete mix proportions and improving project quality.

The influence of machine-made sand grade on concrete properties(xingaonai)

Workability

Reasonable grading can improve the fluidity of concrete, thereby increasing the coverage and filling of sand, making the concrete more uniform and dense, thereby improving its workability, while improper grading may result in insufficient sand coverage or excessive void ratio. , leading to a decrease in the workability of concrete.

Strength

Reasonable gradation and an appropriate amount of stone powder can increase the volume of cement slurry, improve the compactness and uniformity of concrete, thereby improving its strength, while improper gradation and excessive stone powder content may cause concrete segregation and bleeding, and the internal structure Uneven, resulting in dry shrinkage micro-cracks and other defects, reducing its strength.

Durability

Reasonable grading can improve the impermeability and frost resistance of concrete, thereby improving its durability. Improper grading may cause uneven distribution of aggregates in concrete, form seepage channels, and reduce the impermeability of concrete. , reducing its durability. In addition, when using machine-made sand to prepare concrete in special cold areas, air-entraining agents can be appropriately added to improve the frost resistance of the concrete. The specific dosage should be determined by trial mixing.

In addition, the particle shape of machine-made sand will also affect the packing density of machine-made sand, thereby affecting the compactness of concrete. Generally speaking, the greater the content of manufactured sand with spherical or nearly spherical particles, the greater the packing density, which is beneficial to improving the fluidity of concrete and improving the workability and mechanical properties of concrete. The surface of machine-made sand is rough and has many edges and corners. Although it can facilitate the bonding between aggregate and cement when disposing concrete, due to the large edges and roughness of the aggregate, its void rate is also large, which requires more slurry. Therefore, if you want to achieve the same workability, you need more water and gel materials. Otherwise, it may cause the concrete to separate and bleed, affecting the fluidity and strength of the concrete, and may also lead to a reduction in the slump of the concrete.

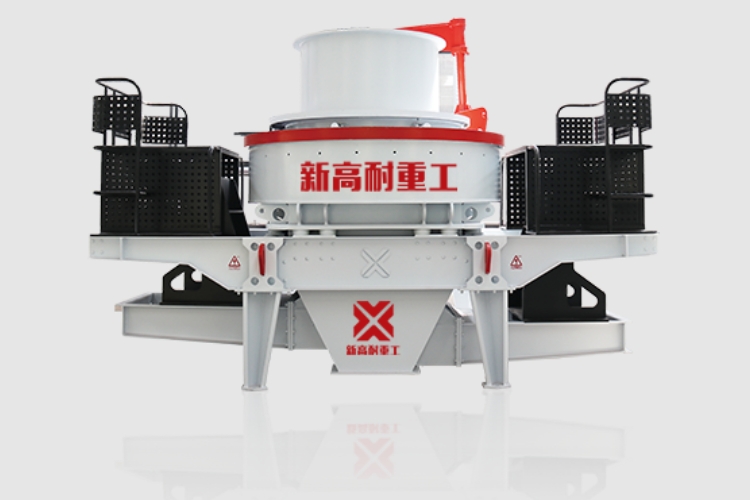

Good machine-made sand equipment can not only improve the production efficiency of machine-made sand, but also effectively improve the quality and performance of machine-made sand through precise particle size control and optimized gradation design. Therefore, choosing good machine-made sand equipment is crucial to improving the gradation of machine-made sand. The importance is self-evident.

Xingao Nai Heavy Industry specializes in the R&D and manufacturing of complete sets of crushing, screening, feeding and conveying equipment in the field of soft rock. All equipment from casting to machining to assembly is controlled by technical engineers at all levels. We strive for excellence and can provide customers with high-quality mechanisms. The complete set of equipment required for the sand production line can not only help users effectively improve the production efficiency of machine-made sand, but also has excellent particle shape and reasonable gradation, which can provide reliable quality building materials for construction, road and other projects.

Superior: No content!

Abajo: No content!

Nuestros productos se han exportado a más de 170 países de África, Asia, América del Sur, Europa, etc. Estamos aquí para ofrecerle mejores productos y servicios.

Copyright © 2024-2030 Xingaonai Group Todos los derechos reservados. Sitemap