xgncrusher

xgncrusher

With the advent of the Industry 4.0 era, intelligent and automated technologies are increasingly widely used in the mining and building materials processing industries. As a leader in this wave, the fully automatic hydraulic roller crusher is using its ability to achieve precise crushing operations. .

1. Technical overview of fully automatic hydraulic roller crusher

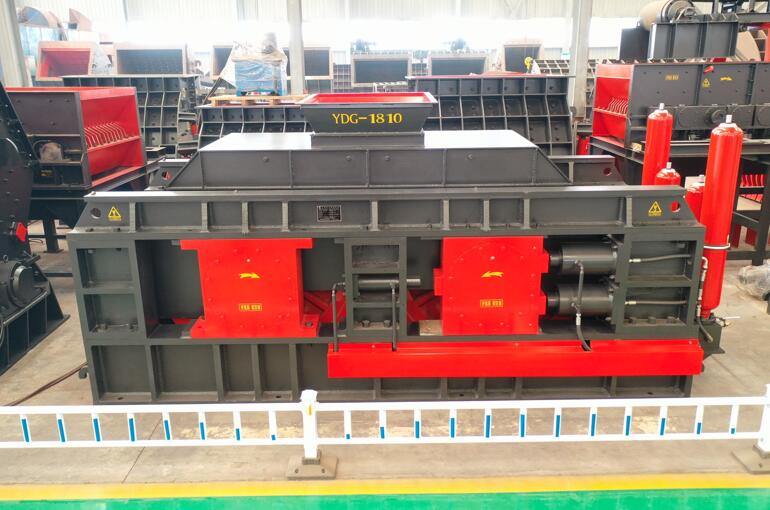

The fully automatic hydraulic double-roller crusher integrates modern mechanical design, hydraulic control and intelligent information technology. Through a highly automated and intelligent operating system, it realizes full-chain automated control from material feeding, crushing processing to finished product output. Its core features are:

Fully automated operation: Utilize sensors and control systems to automatically adjust the hydraulic system based on real-time detection of material properties and equipment status to accurately control the distance between the two rollers and the crushing force, reducing human intervention and improving work efficiency.

Intelligent monitoring and diagnosis: Integrated Internet of Things technology can remotely monitor the operating status of equipment, provide early warning of potential failures, ensure continuous and stable production, and reduce maintenance costs.

Precise particle size control: With the high-precision hydraulic adjustment system, precise control of the particle size of the crushed products can be easily achieved to meet the needs of different industries for high-quality raw materials.

2. Application practice and value reflection

In practical applications, fully automatic hydraulic roller crushers are widely used in mining, construction, cement, metallurgy and other fields, especially in the production of high-quality sand and gravel aggregates, metal ore pretreatment, recycling of waste building materials, etc. Great advantages:

Sand and gravel aggregate industry: Provide high-quality aggregates with uniform particle size and reasonable gradation to support the high-standard construction of key projects such as highways, bridges, and high-rise buildings.

Metal mineral processing: effectively processes medium and low hardness metal ores, provides ideal raw material preparation for subsequent mineral processing procedures, and improves the overall mineral processing efficiency and recovery rate.

Production of environmentally friendly building materials: In the recycling of waste concrete, bricks and other construction waste, efficient crushing and particle size control are achieved to promote resource recycling.

3. Future development trends

Looking forward to the future, fully automatic hydraulic roller crushers will be more closely integrated with cutting-edge technologies such as artificial intelligence and big data analysis, and will develop towards a higher degree of intelligence and personalized customized services. Optimize crushing parameters through machine learning algorithms to further improve the equipment's adaptive capabilities and ability to handle complex materials. At the same time, it enhances the remote control and maintenance capabilities of the equipment and achieves global technical service support.

In short, the continuous technological innovation and application expansion of fully automatic hydraulic roller crushers will bring far-reaching influence and changes to the entire industry.

Superior: No content!

Abajo: No content!

Nuestros productos se han exportado a más de 170 países de África, Asia, América del Sur, Europa, etc. Estamos aquí para ofrecerle mejores productos y servicios.

Copyright © 2024-2030 Xingaonai Group Todos los derechos reservados. Sitemap