Xingaonai

Xingaonai

We know that the vibration force of the vibrating screen is generally generated by the rotation of the motor. The rotation direction of the vibrating screen is the rotation direction of the vibration motor. The number and rotation direction of motors of different types of vibrating screens are also different. Xingaonai will show you the working principle and forward and reverse functions of the vibration motor:

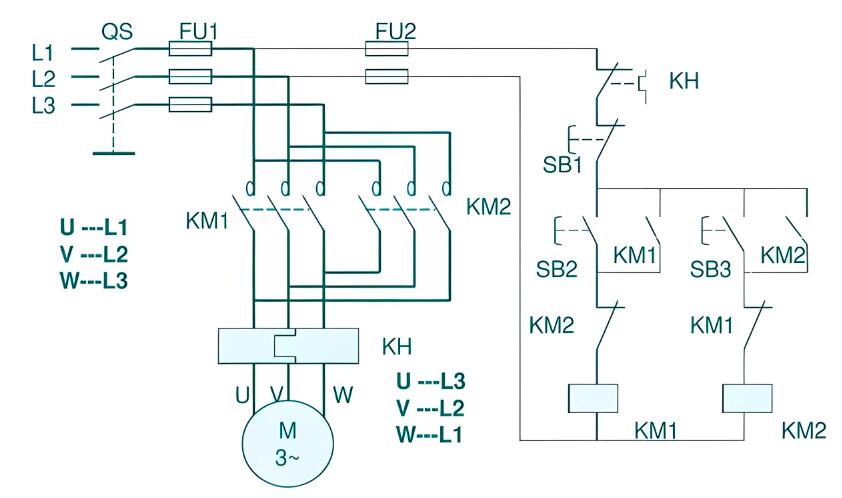

The vibrating screen controls the screening effect by changing the vibration direction and vibration amplitude. This flexibility allows the vibrating screen to adapt to different screening needs. Specifically, the vibration motor of the vibrating screen can achieve forward and reverse rotation by controlling the positive and reverse polarity of the power supply, thereby changing the direction of the vibration force. When the polarity of the power supply is the same as the rotation direction of the vibration motor, the vibrating screen vibrates forward; when the polarity of the power supply is opposite to the rotation direction of the vibration motor, the vibrating screen vibrates backward. This design allows the vibrating screen to select the forward and reverse direction of the vibration motor according to actual conditions when in use, in order to achieve the best screening effect. Different types of vibrating screens, such as rotary vibrating screens, linear screens, swing screens, etc., have different motor rotation directions, but in general, they can achieve forward and reverse rotation by adjusting the rotation direction of the motor, thereby optimizing the screening process.

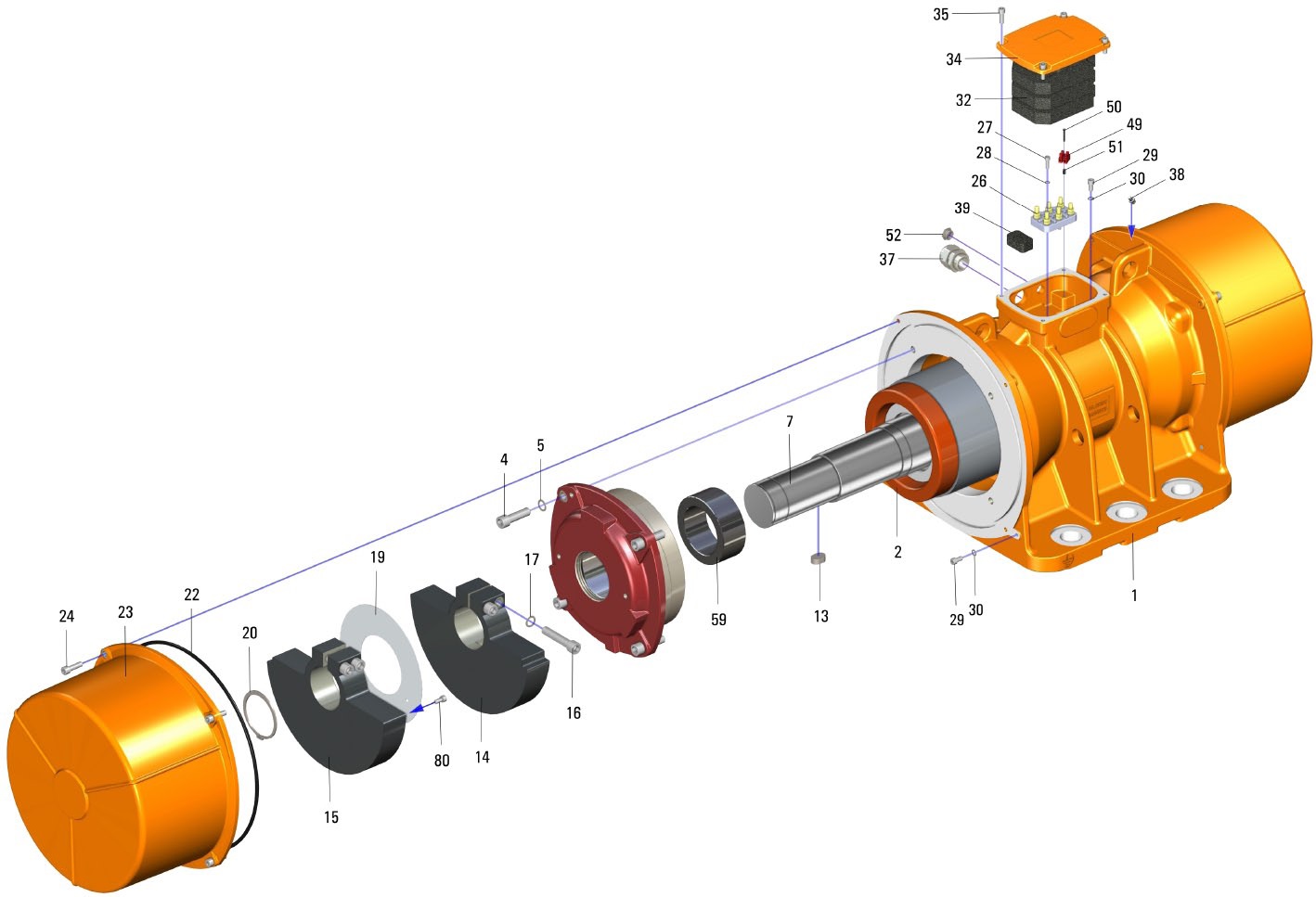

A vibration motor is a device that converts electrical energy into mechanical energy. It usually uses a three-phase asynchronous motor and converts the power frequency into a suitable vibration frequency through a frequency converter. The main components of a vibration motor include a rotor, a stator, a bearing, a coupling, etc. When working, the centrifugal force is generated by the rotation of the rotor, thereby achieving a vibration effect.

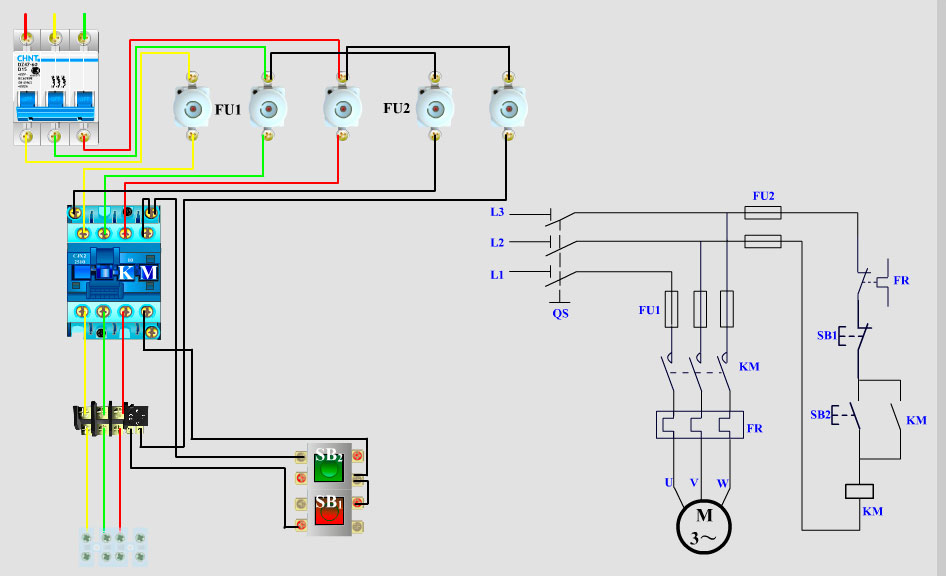

Vibration motors usually have forward and reverse functions, which can be achieved by changing the direction of the current. This function is mainly used in equipment such as vibrating screens and conveyors to meet the needs of different working conditions. For example, in a vibrating screen, the vibration intensity and direction need to be adjusted according to the type of material and screening accuracy. By changing the forward and reverse rotation of the vibration motor, different material screening effects can be achieved.

There is a certain difference in the material screening effect between the forward and reverse rotation of the vibrating screen. Forward rotation has a better screening effect for materials with high water content, because the oscillation in the forward direction will make the material flow quickly on the screen surface, and the disturbance will also make the water in the material flow out quickly, thus achieving a better screening effect. The load direction is also different. When the load acts on the material on the screen in the forward direction during forward rotation, it is easy for the material to move along the screen hole direction, increasing the probability of the material passing through the screen, but it is also easy to cause wear of the screen. When the load acts on the material on the screen in the backward direction during reverse rotation, the material can be squeezed on the screen, thereby increasing the screening efficiency, but it will also increase the load on the motor.

Generally speaking, forward rotation is generally selected in the coarse screening process, and reverse rotation is generally selected in the fine screening process. In some special cases, such as when the material particles are irregular in shape or when the screening accuracy is required to be high, forward rotation and reverse rotation can also be used alternately, but the specific choice needs to be determined according to the actual situation and production needs.

In summary, the forward and reverse rotation of the vibration screen motor can be determined by observing the direction of material movement, checking the motor wiring, using tools to detect, and observing the direction of motor rotation. Whether you choose forward or reverse rotation, you should pay attention to the wear of the screen and replace the worn screen in time to avoid affecting the screening efficiency; at the same time, you also need to pay attention to the control of the motor load, especially when choosing reverse rotation, you should avoid overloading the motor.

Superior: No content!

Abajo: No content!

Nuestros productos se han exportado a más de 170 países de África, Asia, América del Sur, Europa, etc. Estamos aquí para ofrecerle mejores productos y servicios.

Copyright © 2024-2030 Xingaonai Group Todos los derechos reservados. Sitemap