Xingaonai

Xingaonai

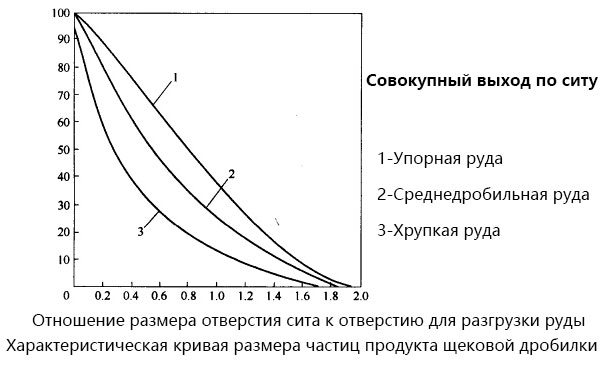

The crushing process of the jaw crusher is a complex mechanical and physical process. Changes in various process parameters will affect the crushing particle size of the product. In order to intuitively reflect the crushing effect and process parameter adjustment of the jaw crusher, we can analyze it by drawing the product particle size characteristic curve. The product particle size characteristic curve is analyzed by measuring the number of particles of different particle sizes output from the jaw crusher discharge port at different times, and then drawing a curve of the number of particles and the corresponding particle size. Through this curve, we can understand the crushing performance and process parameter adjustment of the jaw crusher more intuitively.

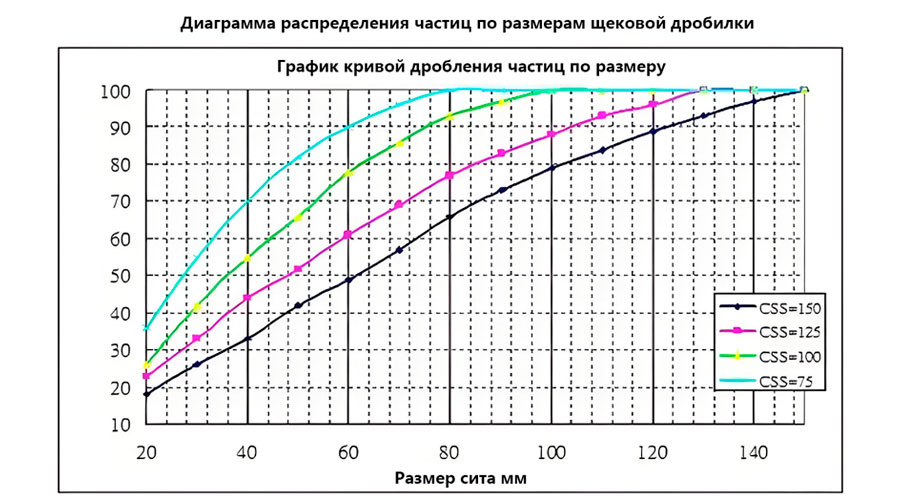

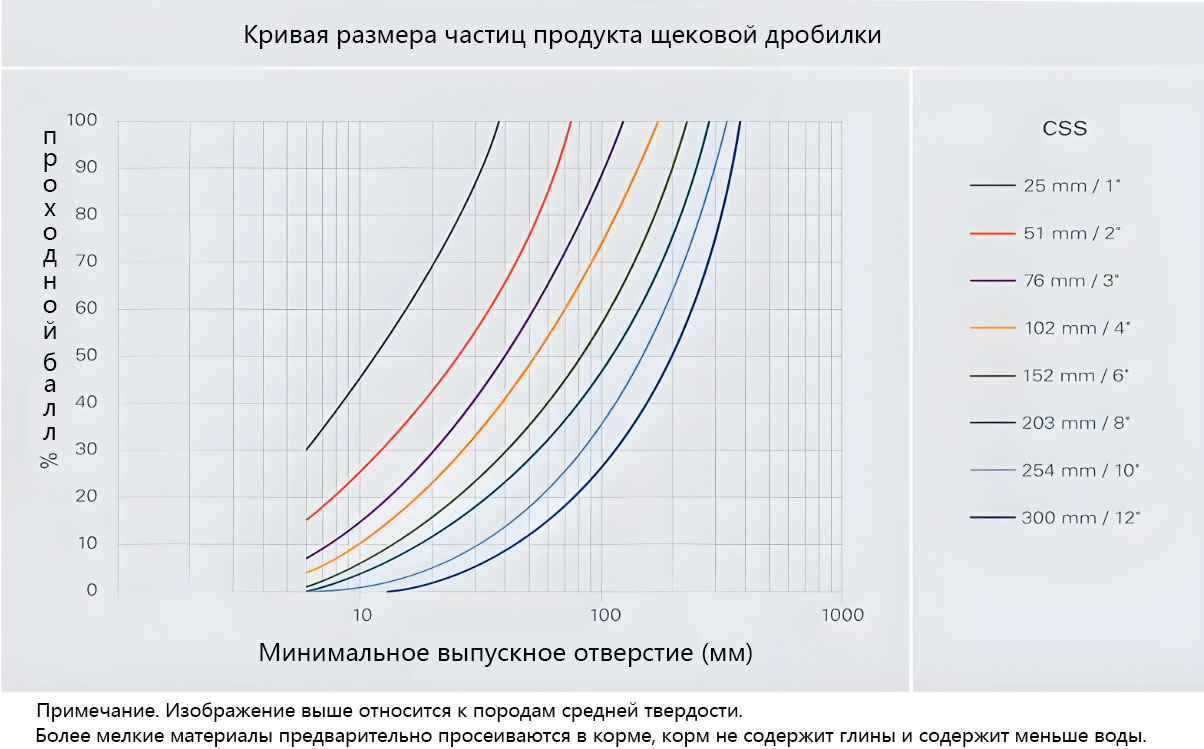

The particle size characteristic curve of the jaw crusher mainly has two parameters, namely the cumulative particle size curve and the distribution particle size curve. The cumulative particle size curve refers to the particle size distribution curve generated when the crusher is continuously crushing. The distribution particle size curve refers to the percentage of particles of various particle sizes in the product, which is often used for product classification and grading.

Through the analysis of the particle size characteristic curve, we can get the following information:

Crushing capacity of the jaw crusher: the flatter the curve is, the better the crushing capacity of the jaw crusher is, and the more uniform the product particle size can be obtained;

Optimization and adjustment of the jaw crusher: by comparing the product particle size characteristic curves at different time points, the crushing effect of the jaw crusher under different process parameters and the adjustment effect of the adjustable parameters can be obtained, thereby optimizing the production process;

Crushing efficiency of the jaw crusher: the maximum value of the curve represents the crushing efficiency of the jaw crusher, and the crushing efficiency can be improved by adjusting the crushing chamber structure and process parameters.

The application of the particle size characteristic curve of the jaw crusher is mainly to evaluate the production efficiency and quality of the jaw crusher through the curve parameters. The following are several commonly used evaluation indicators:

Uniformity coefficient

The uniformity coefficient is an indicator of the distribution particle size curve, which reflects the particle size distribution of the product, and its value range is 0 to 1. When the uniformity coefficient is equal to 1, it means that the particle size distribution of the product is very uniform; when the uniformity coefficient is less than 1, it means that the particle size distribution of the product is becoming more and more uneven. Therefore, the larger the uniformity coefficient, the higher the crushing efficiency of the jaw crusher.

Fineness modulus

The fineness modulus is a parameter for classifying the screened materials produced by the jaw crusher. In the production process of the jaw crusher, this parameter can reflect the degree of fineness of the product. The smaller the fineness modulus, the finer the product produced by the jaw crusher, and it may need to be crushed or screened again. Therefore, the fineness modulus is one of the important indicators for evaluating the fineness distribution of the jaw crusher product.

Crushing ratio

The crushing ratio is a parameter used to evaluate the crushing efficiency of the jaw crusher. It reflects the energy and time required for the jaw crusher to crush the raw materials into particles of the required size during the crushing process. The larger the crushing ratio, the higher the crushing efficiency and the smaller the particle size of the crushed product.

Through the above analysis, we can know that the particle size characteristic curve of the jaw crusher product can reflect the particle size distribution, output and crushing efficiency of the jaw crusher product, which has important guiding significance for evaluating the production efficiency and quality of the jaw crusher. Therefore, in the production process of the jaw crusher, monitoring and optimizing the particle size characteristic curve of the product plays a vital role in improving the production efficiency and quality of the crusher.

Superior: No content!

Abajo: No content!

Nuestros productos se han exportado a más de 170 países de África, Asia, América del Sur, Europa, etc. Estamos aquí para ofrecerle mejores productos y servicios.

Copyright © 2024-2030 Xingaonai Group Todos los derechos reservados. Sitemap