Xingaonai

Xingaonai

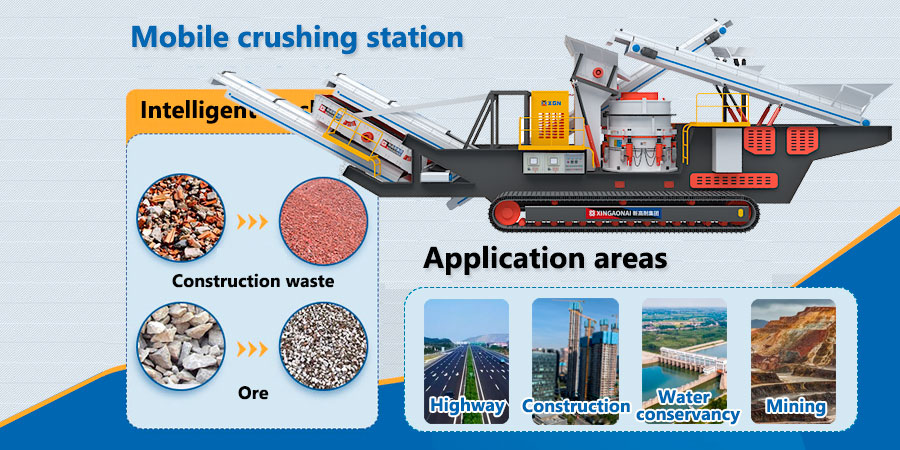

The equipment used in the crushing production line is usually divided into fixed crushers and mobile crushers. They each have different advantages and disadvantages and are suitable for different work scenarios and needs. From appearance to internal structure design, as well as the scope of use, feed particle size, discharge particle size, production line configuration, discharge particle size, price, etc. are all different. The following is a brief answer from Xin Gaonai Heavy Industry to the advantages and disadvantages of fixed and mobile crushers:

1. Convenient and flexible: Mobile crushers can be put into production after installation and commissioning at the factory. Temporary and periodic crushing production lines can be quickly established. They can be moved to the required work site at any time to adapt to different work needs. They are especially suitable for projects that require frequent migration.

2. Nearby processing mode: Mobile crushers are suitable for various work sites and can completely save the transportation costs generated during the transportation of sand and gravel. In response to increasingly stringent environmental protection policies, it can effectively avoid secondary pollution caused by the transportation process.

3. High degree of automation: PLC control system, with a high degree of automation, can monitor the working status of the equipment, and is equipped with protection devices. It can monitor and protect the equipment in real time to ensure higher safety of the equipment.

1. High cost: Mobile crushers have high technical investment costs, so the price is high, and the subsequent maintenance and repair are complicated, and the labor cost is high.

2. Limited output: Due to the need to consider the portability and adaptability of the equipment, the crushing capacity of the mobile crusher is lower than that of the fixed crusher, and its output is equivalent to a small fixed stone production line.

3. Poor stability: The stability of the mobile crusher may be affected by movement and transportation, and it is necessary to pay attention to the stability and safety of the equipment during use.

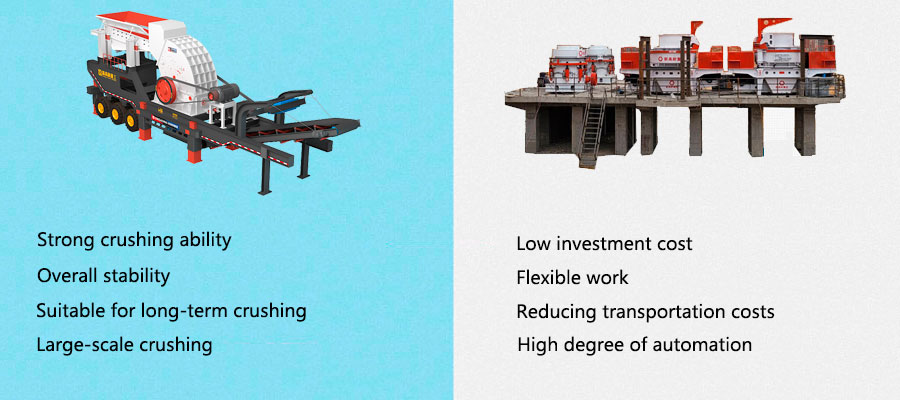

1. Good stability: Fixed crushers are usually placed in a fixed position, their structure is more stable, and they can run for a long time. They are suitable for scenes that require continuous large-scale crushing operations.

2. High production efficiency: Fixed crushers have low prices, easy maintenance, high production efficiency, and large processing capacity. High-capacity production lines can be designed according to production needs. It is mainly used in manufacturers with relatively concentrated stones and relatively stable supply and sales.

3. Convenient maintenance: Due to the fixed position of the crusher, operators can more easily make fine adjustments to the equipment, which is easier to maintain than mobile production line equipment.

High investment cost: Building and installing fixed crushers requires a certain amount of investment, site design, etc. When installing the equipment, in order to fix it, it is necessary to use concrete to lay the foundation, and civil engineering requires a large amount of investment.

Low management efficiency: After completion, there are still many uncontrollable factors, and multiple operators are required. There are many equipment, which is not conducive to efficient management.

Fixed and inflexible: Due to the fixed position, it cannot adapt to the operation scene that requires frequent migration.

In summary, the fixed crusher has strong crushing capacity and overall stability, which is suitable for scenes that require long-term and large-scale crushing production, while the mobile crusher has a lower investment cost and is more suitable for operations that require flexibility and frequent migration. The type of crusher to be selected should be determined according to specific work needs and budget.

If you want to know more about the crusher, please call or consult online, leave a message, and Xin Gaonai Heavy Industry will send professionals to answer your questions.

Superior: No content!

Abajo: No content!

Nuestros productos se han exportado a más de 170 países de África, Asia, América del Sur, Europa, etc. Estamos aquí para ofrecerle mejores productos y servicios.

Copyright © 2024-2030 Xingaonai Group Todos los derechos reservados. Sitemap