Xingaonai

Xingaonai

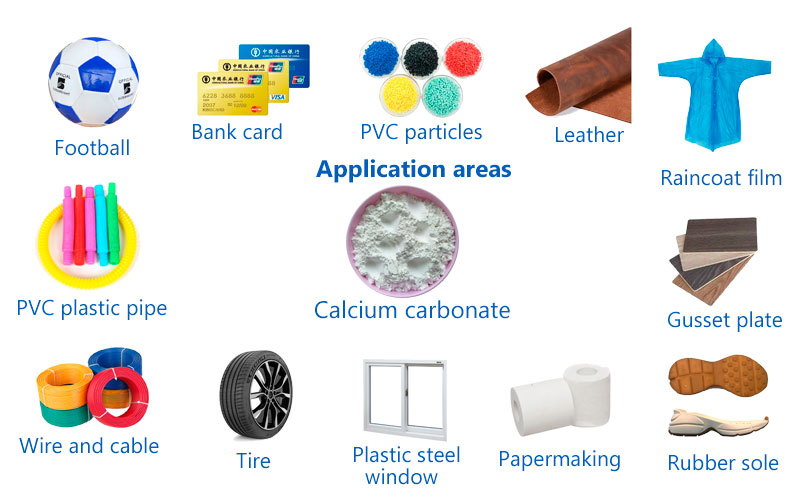

Calcium carbonate is an important inorganic compound and is widely used in industrial production.

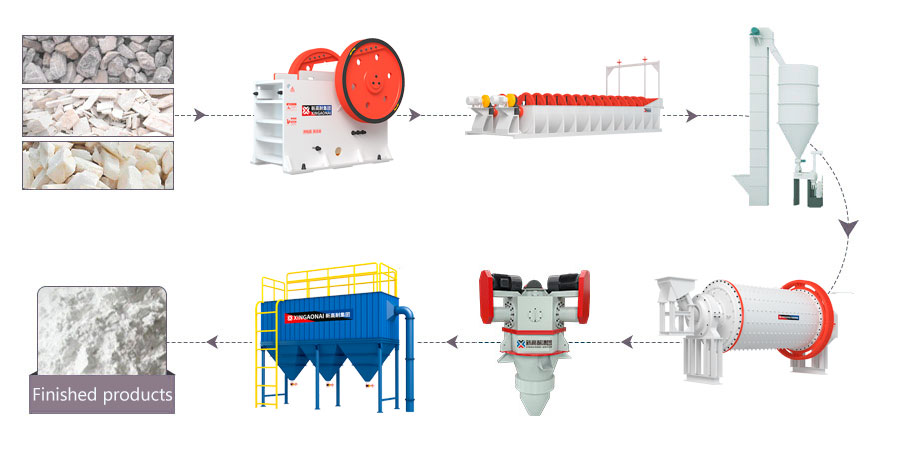

Grinding of calcium carbonate is a very critical process. Calcium carbonate powder is mainly produced by crushing, screening, washing and other industrial processes of inorganic ores such as natural marble, limestone, and calcite.

The purpose of grinding is to control the size and shape of raw material particles within a certain range to meet the needs of industrial production. It is widely used in building materials, plastics, rubber, cosmetics, food and other fields.

The calcium carbonate production line is mainly composed of crushers, mills, packaging machines, elevators, conveying devices and other equipment. The mill is the main equipment for calcium carbonate processing and powder making.

The widely used mills on the market include Raymond mills, vertical mills, ultrafine vertical mills, ring roller mills and other types.

Raymond mill: suitable for 80-400 mesh coarse powder processing. It is a traditional and common grinding equipment suitable for processing materials with moderate hardness, such as calcium carbonate. It has a simple structure, stable operation and low maintenance cost.

Vertical mill: suitable for 80-600 mesh coarse powder processing, with the advantages of high production efficiency, low energy consumption, and small footprint. It is widely used in large-scale calcium carbonate production.

Ring roller mill: suitable for 325-1250 mesh fine powder processing, it has a better effect on the production of calcium carbonate powder with higher fineness, and can meet some application scenarios with strict requirements on product fineness.

Ultrafine mill: suitable for 600-3250 mesh ultrafine powder processing, it can grind calcium carbonate to very fine particle size, suitable for high-end fields, such as electronic materials, medicine and other industries that require extremely high calcium carbonate fineness.

There are two main methods for grinding calcium carbonate: dry grinding and wet grinding.

Dry grinding

Process: raw material-> first crushing-> second crushing-> classifier-> elevator-> grinder-> dust collector-> powder selector-> finished product

Dry grinding refers to grinding under water-free conditions. The basic principle of dry grinding is to put the raw material particles into the grinder and grind them by mechanical force. Among them, commonly used grinding machines include ball mills, grinding mills and vibration mills. Ball mills are a commonly used grinding machine. The grinding principle is to put the raw material particles into the grinding balls and grind them through the collision and friction between the balls and the grinding wall.

The advantages of dry grinding are high grinding efficiency, the ability to grind the raw material particles quickly and evenly, and the process is simple, the production process is short, and there is no need to set up subsequent dehydration processes such as filtration and drying. It has the characteristics of simple operation, easy control, low investment, and low operating costs.

Wet grinding

Process: calcium carbonate powder-> dispersion tank-> intermediate tank-> grinder 1-> grinder 2-> grinder 3-> vertical vibrating screen-> intermediate storage tank-> particle size classifier-> product storage tank-> finished product

Wet grinding refers to grinding in the presence of water. The basic principle of wet grinding is to put the raw material particles into the grinder, add an appropriate amount of water and lubricant, and grind them through mechanical force and liquid action. Commonly used wet grinding machines include bead mills, three-roll mills, etc. A bead mill is a grinding machine that uses grinding beads to grind raw material particles. It has the advantages of high grinding efficiency, uniform grinding, and high grinding precision.

Advantages of wet grinding: Adding water in the production process makes the powder easy to disperse, and water has a partial grinding aid effect, which is conducive to ultrafine grinding. Therefore, the wet production process has the advantages of fine product particle size and narrow particle size distribution.

In short, calcium carbonate grinding is an indispensable link in industrial production. Dry grinding and wet grinding are commonly used grinding methods, each with its own advantages and disadvantages. When choosing a grinding method, it is necessary to choose according to specific production needs and equipment conditions. At the same time, it is necessary to pay attention to the operating specifications during the grinding process to ensure the grinding effect and operation safety.

If you want to know more about calcium carbonate grinding equipment, you can contact our customer service and the manufacturer will ask experts to give you detailed answers!

Many customers may not know what the relationship is between mesh, micrometer and millimeter. The following conversion table is for reference:

| mesh | Micrometer | Millimeter |

| 100 mesh | 150µm | 0.15mm |

| 200 mesh | 74µm | 0.074mm |

| 325 mesh | 45µm | 0.045mm |

| 400 mesh | 38µm | 0.038mm |

| 600 mesh | 23µm | 0.023mm |

| 800 mesh | 18µm | 0.018mm |

| 1250 mesh | 10µm | 0.01mm |

| 1750 mesh | 8µm | 0.008mm |

| 2500 mesh | 5µm | 0.005mm |

| 5000 mesh | 2.5µm | 0.0025mm |

| 8000 mesh | 1.6µm | 0.0016mm |

Superior: No content!

Abajo: No content!

Nuestros productos se han exportado a más de 170 países de África, Asia, América del Sur, Europa, etc. Estamos aquí para ofrecerle mejores productos y servicios.

Copyright © 2024-2030 Xingaonai Group Todos los derechos reservados. Sitemap