Xingaonai

Xingaonai

Cone crushers are suitable for crushing stones with high hardness and low water content, suitable for medium and fine crushing of various ores, and small and medium-sized rock production lines. They are widely used in many departments such as mining, smelting, building materials, roads, railways, water conservancy and chemical industries.

Jaw crushers are suitable for crushing stones with low hardness and high water content, suitable for coarse and medium crushing of various ores and large-scale mining production lines of rocks, and are widely used in mining, building materials, roads, railways and other industries.

Cone crushers mainly operate on the lamination principle. The motor drives the eccentric sleeve to rotate through the transmission device. The moving cone rotates and swings under the force of the eccentric sleeve. The section of the moving cone close to the static cone becomes the crushing chamber. The material is crushed by multiple extrusions and impacts of the moving cone and the static cone.

The jaw crusher crushes materials by the principle of rolling the moving jaw plate and the static jaw plate against each other. The crushing chamber is V-shaped. The gap between the two jaw plates is used to crush the materials, and then the materials are crushed into particles of the required size by the periodic movement of the jaw plates. The material fragments are discharged from the bottom under the action of gravity.

The cone crusher is mainly composed of a frame, a mortar wall, a crushing wall, a main shaft, a transmission shaft, an adjustment sleeve and an eccentric sleeve, and has a complex structure.

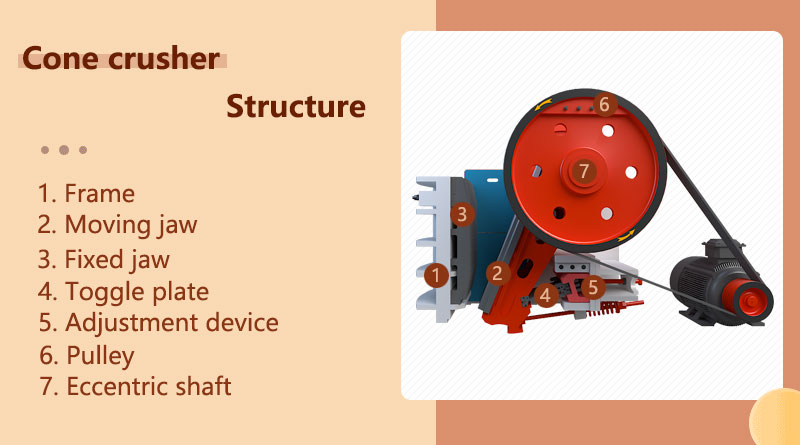

The jaw crusher is mainly composed of a frame, a moving jaw, a fixed jaw, a toggle plate, a pulley, an eccentric shaft, an adjustment device and other components, and has a relatively simple structure.

In terms of crushing efficiency, the cone crusher has obvious advantages.

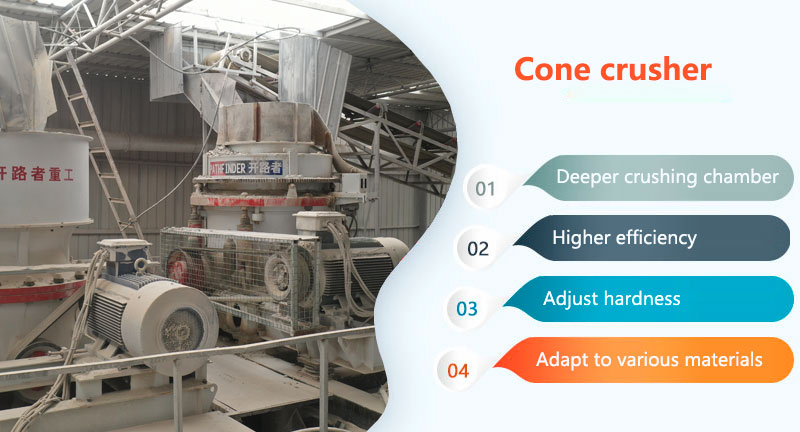

The crushing chamber of the cone crusher is deeper, which can make the materials more fully crushed during the crushing process, thereby improving the crushing efficiency. In addition, the cone parts of the cone crusher can be adjusted according to the hardness and stability of the material, so as to better meet the crushing needs of various materials.

The crushing chamber of the jaw crusher is shallow, and the material is easy to accumulate during the crushing process, which affects the crushing efficiency.

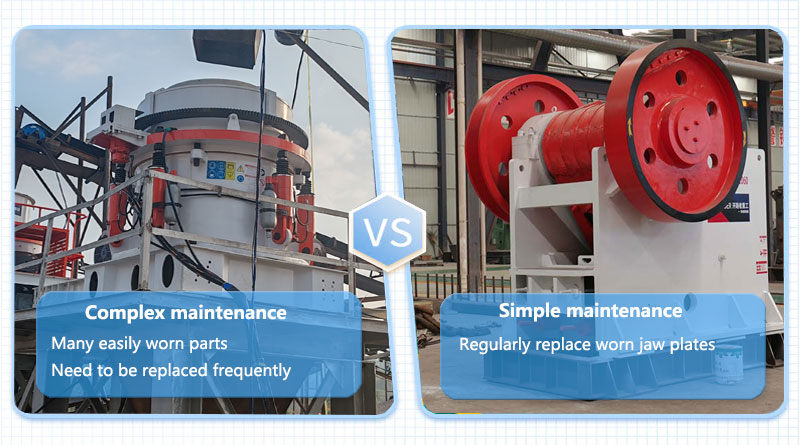

In terms of maintenance, the cone crusher is more complicated than the jaw crusher.

The gap between the conical parts and the shell of the cone crusher is small, and more delicate processing and adjustment are required to maintain normal operation. In addition, the conical parts of the cone crusher are easily worn and need to be replaced frequently, which increases the maintenance cost.

The jaw crusher is relatively simple, and only the worn jaw plate needs to be replaced regularly.

The above is the difference between the cone crusher and the jaw crusher. Through comparison, their differences are explained from five aspects: application field, working principle, structural structure, crushing efficiency, and maintenance difficulty. When choosing a crusher, it is necessary to select suitable crushing equipment according to the actual situation, and perform regular maintenance to achieve better crushing effect and economic benefits.

If you want to know more about the crusher, please call or consult online, leave a message, and Xin Gaonai Heavy Industry will send professionals to answer your questions.

Superior: No content!

Abajo: No content!

Nuestros productos se han exportado a más de 170 países de África, Asia, América del Sur, Europa, etc. Estamos aquí para ofrecerle mejores productos y servicios.

Copyright © 2024-2030 Xingaonai Group Todos los derechos reservados. Sitemap