Xingaonai

Xingaonai

Impact crusher and hammer crusher are both common crushing equipment in the mining industry. In sand and gravel plants, impact crushers and hammer crushers are often seen. Both are widely used in mining, metallurgy, cement, building materials, chemicals, hydropower and other industries. The technical structure, working principle, material handling, maintenance cost, etc. of these two crushers are somewhat different. What is the difference between these two crushers? Which crusher is more popular and which crusher is better?

There is a big difference between the impact crusher and the hammer crusher when crushing materials, which is caused by the difference in their plate hammers.

The impact crusher uses impact energy to crush materials. Driven by the motor, the rotor rotates at high speed. When the material enters the plate hammer action area, it collides with the plate hammer on the rotor and is crushed. Then it is thrown onto the impact device and crushed again, and then bounces back from the impact liner to the plate hammer action area and crushed again. This process is repeated, and the material enters the first, second, and third impact chambers from large to small and is repeatedly crushed until the material is crushed to the required particle size and discharged from the discharge port. Adjusting the gap between the impact frame and the rotor can achieve the purpose of changing the material discharge particle size and material shape;

The hammer crusher is also a device that crushes materials in the form of impact. The motor drives the rotor to rotate at high speed in the crushing chamber. The material is fed into the machine from the upper feed port and crushed by the impact, impact, shearing and grinding of the high-speed hammer. At the bottom of the rotor, there is a screen plate. The particles smaller than the size of the screen hole in the crushed material are discharged through the screen plate, and the coarse particles larger than the size of the screen hole are retained on the screen plate and continue to be hit and ground by the hammer, and finally discharged from the machine through the screen plate.

Both impact crushers and hammer crushers can adjust the size of the finished particles. Since the impact crusher does not have a grate screen at the bottom, the adjustment of the product particle size is mainly controlled by adjusting the rotor speed or rotor diameter, adjusting the size of the distributor opening, and adjusting the gap of the grinding chamber.

For the hammer crusher, the adjustment of the finished particle size can be controlled by adjusting the size of the screen plate gap. According to this situation, the impact crusher can more effectively handle materials with a large water content and avoid blockage.

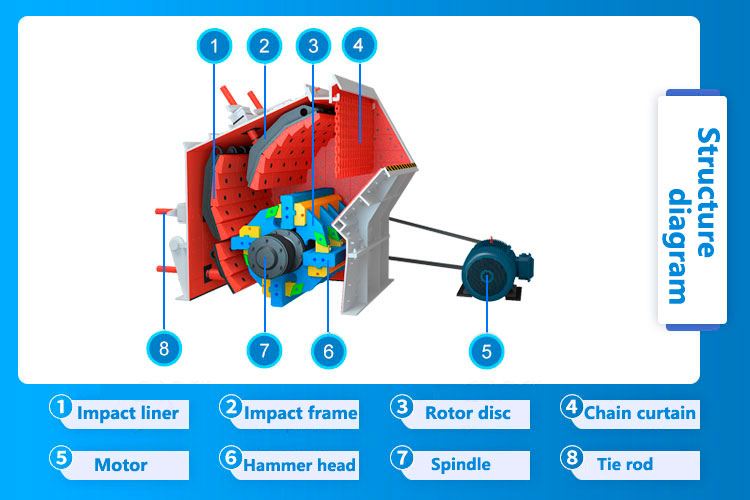

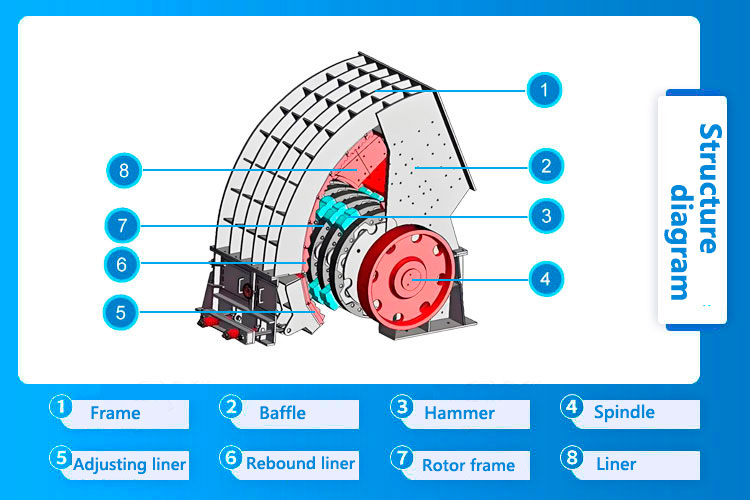

There are still some differences in the structure between the impact crusher and the hammer crusher.

For the crushing chamber, the impact crusher's crushing chamber is relatively larger, and the feed port is also relatively large. The main components of the impact crusher include springs, railings, front impact frames, rear impact frames, impact liners, square steel, impact liner bolts, flip cover devices, spindles, plate hammers, rotor frames, liners, locking blocks, clamping blocks, etc.

Comparatively speaking, the crushing chamber of the hammer crusher is smaller, and its sealing performance is better than that of the impact crusher. Less dust pollution will be generated during the material crushing process, which will have an environmental advantage. The main components of the hammer crusher are composed of a casing, a rotor, a spindle, a hammer head, an impact liner, a screen plate, a motor, etc.

Due to the differences in its technical structure and working principle, the impact crusher can not only process softer materials, but also materials with greater hardness, such as granite, river pebbles and other high-hardness materials.

The hammer crusher can only process materials with lower hardness, such as limestone, coal gangue, etc., and materials with compressive strength within 200 MPa. Because there is no grate bar at the bottom of the impact crusher, the product particle size is determined by the gap between the impact plate and the hammer head, so when the water content of the material is too high, it can effectively avoid the phenomenon of grate bar clogging when crushing wet materials.

The hammer crusher increases the possibility of clogging due to the grate bar factor, so it cannot handle materials with high humidity. In comparison, the working range of the impact crusher is wider.

In the early stage of purchase, the price of the impact crusher is generally higher than that of the hammer crusher. However, due to the differences in structure and work between the impact crusher and the hammer crusher, there will be certain differences in later maintenance.

In terms of the life of wearing parts, the wear of the impact crusher hammer only appears on the side facing the material. When the rotor speed is normal, the feed will fall to the surface of the hammer (striking surface), and the back and sides of the hammer will not be worn. Moreover, the bottom grinding rod is also easy to replace, and the utilization rate of its plate hammer is as high as about 45%-48%.

The hammer head of the hammer crusher is in a suspended state, and wear occurs on the top, front, back and side. There are more than 100 hammer heads. Replacing a set of hammer heads takes a lot of time and manpower, and the inspection and maintenance costs are high. The rotor and bottom screen plate of the hammer crusher may also be worn during operation, and replacement is relatively complicated.

Both the impact crusher and the hammer crusher use the impact force of the plate hammer and the hammer head running at high speed to crush the material. The products are mostly cubic, and the particle shape of the output is very popular.

The use of the impact crusher in the production line is more common because it can handle a wide variety of materials and the output particle shape is also better. It is mostly used in the secondary crushing link of the crushing and sand making production of various stone materials.

Relatively speaking, the application range of the hammer crusher is smaller. The heavy hammer crusher has a large feed inlet, a relatively small discharge particle size, a large crushing ratio, and the crushed material does not need secondary crushing, but can be formed in one time. The customer's crushing production can use only one heavy hammer crusher, with less investment.

To ask which equipment is more popular, I can only say that they each have their own application areas of expertise, and it depends on the customer's own choice.

In summary, the impact crusher and the hammer crusher have their own advantages and disadvantages. When choosing, it is necessary to weigh them according to the specific application requirements. In summary, the impact crusher has more advantages than the hammer crusher in stone crushing, but the initial investment is higher than the hammer crusher.

If you need to process high-hardness materials, pursue uniform product particle size and have certain requirements for noise, the impact crusher may be more suitable;

If you need to produce on a large scale, process low-hardness materials and have a certain tolerance for equipment size and maintenance difficulty, the hammer crusher may be more suitable.

If you want to know more about the crusher, please call or consult online, leave a message, and Xin Gaonai Heavy Industry will send professionals to answer your questions.

Superior: No content!

Abajo: No content!

Nuestros productos se han exportado a más de 170 países de África, Asia, América del Sur, Europa, etc. Estamos aquí para ofrecerle mejores productos y servicios.

Copyright © 2024-2030 Xingaonai Group Todos los derechos reservados. Sitemap