Xingaonai

Xingaonai

Slag is solid waste generated during industrial processing and metal smelting production. These slags may also pollute the environment and should be properly handled. We can use scientific and technological means to recycle and reuse them, turning waste into treasure and making new resources.

Slag can be divided into many types such as steel slag, blast furnace slag, and ferroalloy slag.

Blast furnace slag: After high-temperature iron smelting, impurities such as alumina and silica in iron ore react with lime to produce a molten material mainly composed of aluminosilicates and silicates. After cooling, the loose and porous granular material is blast furnace slag, which is a Types of slag.

Steel slag: The slag produced in steelmaking production is mainly composed of silicates, phosphides, metal oxides, and a small amount of sulfides. Steel slag has a large hardness and is difficult to crush. After special treatment, it can be used as backfill and building materials. In addition, steel slag contains metallic iron and other useful elements, which can be recycled and reused.

Ferroalloy slag: It is mainly composed of higher elements such as chromium, silicon, and manganese. It is the slag produced in the process of smelting ferroalloys. This kind of slag contains metal elements, which can be recycled and reused. After use, it can also be used as raw materials for soil improvement and building materials.

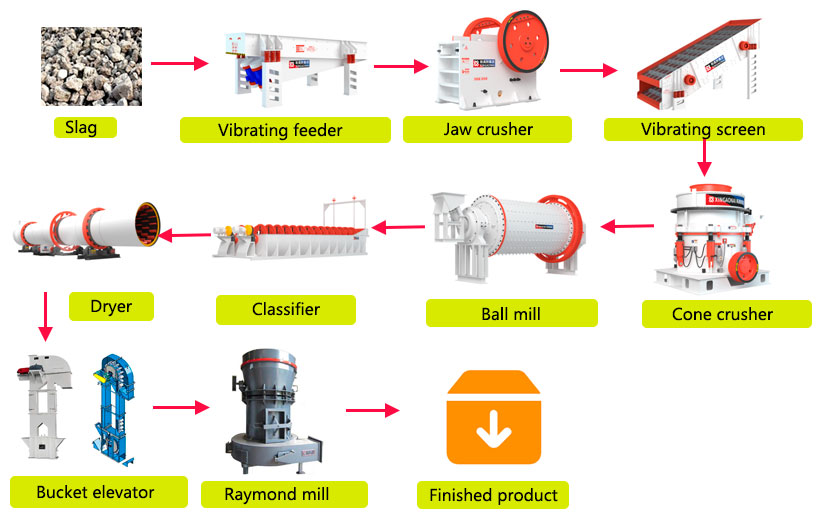

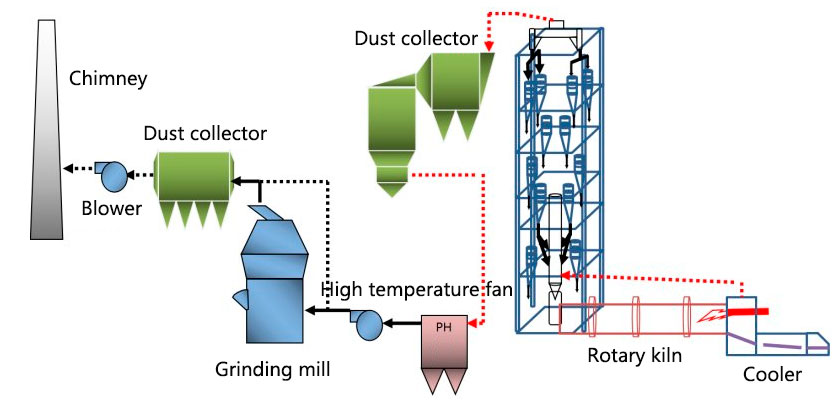

Usually, slag needs to be processed into slag powder. This requires a micro-powder production line to achieve this. The main process of this production line is that the slag is picked up and fed by a transportation tool and transported by a belt conveyor. In this process, the iron remover and vibrating screen are used for iron removal and screening, and the elevator is sent to the ball mill for grinding. After grinding, it is sent to the powder selector through a hot air furnace for powder selection and drying at the same time. The slag powder that meets the requirements will be transported to the dust collector for collection, and then the air conveying chute and elevator will be stored in the finished product warehouse.

The following equipment is mainly used in slag processing: Bibrating Feeder, Jaw crusher, Vibrating screen, Cone Crusher, ball mill, classifier, Dryer, bucket elevator, Raymond mill, etc.

Ball mill

The slag grinding equipment we use is a ball mill. There are steel balls of different specifications inside the ball mill. The cylinder rotates to make the steel balls reach a certain height, which has an attack and grinding effect on the material. The ball mill has a second bin, which can be used for secondary grinding to make the powder finer.

Ball mill advantages

Energy saving and low consumption: It adopts self-aligning double-row radial spherical roller bearings, with small running resistance, significant energy-saving effect, and can be used both dry and wet.

High output and high efficiency: large inlet and outlet diameters, increased processing; reasonable configuration of steel balls, good grinding effect.

Wear-resistant and durable: The wearing parts are all cast with high-quality materials, with first-class casting technology and good wear resistance, which effectively reduces the cost of use.

Stable operation: It is installed separately, simple and easy to operate; there is no inertial impact during the crushing process, and the equipment runs smoothly.

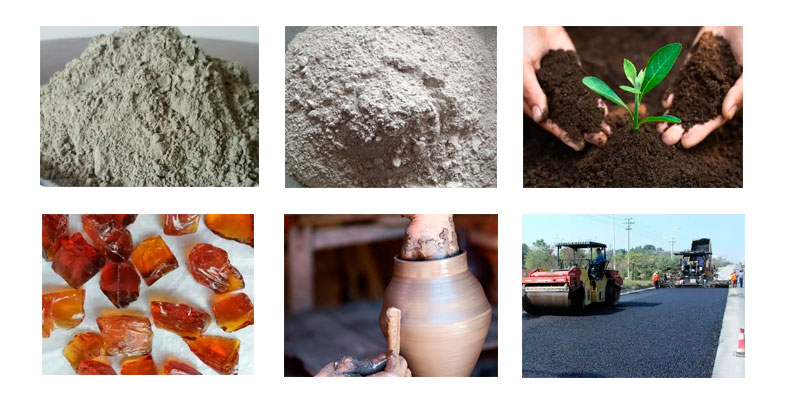

There are two main uses for slag:

Producing various cements, such as slag silicate cement and slag cement;

It can be used as raw materials, such as fertilizers, glass and ceramics;

Slag cement

Making slag cement not only reduces production costs, but also saves a lot of energy and reduces environmental pollution. Slag has a high hardness and is not easy to grind. The grinding technology of slag determines the quality and output. At the same time, the use of slag micropowder in cement production is directly related to the grinding technology and the activity of slag powder. The proportion of slag powder in cement is related to the activity. The higher the activity, the higher the proportion of slag powder can be mixed, and the higher the strength of the produced cement.

Slag soil

The commonly used methods include acid leaching, leaching, alkali leaching, etc. After treatment, some nutrients needed by plants can be released, thereby improving the fertility of the land, so as to achieve the purpose of improving soil quality and improving plant growth. No matter what treatment method is used, it must be ensured that it will not cause harm to the environment and human health.

Superior: No content!

Abajo: No content!

Nuestros productos se han exportado a más de 170 países de África, Asia, América del Sur, Europa, etc. Estamos aquí para ofrecerle mejores productos y servicios.

Copyright © 2024-2030 Xingaonai Group Todos los derechos reservados. Sitemap