Xingaonai

Xingaonai

With the continuous development of science, technology and economy, sand making machines play a core role in mining and building materials processing, and are specially designed for fine sand making and shaping operations in mines. It is difficult for the traditional single sand making machine to gain a foothold in the current market. Compared with other crushing machines, the new sand making machine can often achieve higher output output while ensuring uniform crushing particle size and excellent shape, providing users with Bring significant economic benefits and production efficiency improvements. Faced with the dazzling array of sand making machines with diverse performances on the market, the correct selection of high-yield and suitable sand making equipment is crucial to ensure the high-quality production of machine-made sand. Xingao Nai Heavy Industry will introduce to you in detail:

The impact sand making machine has been upgraded in terms of structural characteristics, production output, and sand formation rate. It adopts the working principle of combining "stone on stone" and "stone on iron" to crush, shape and shape the raw materials entering the crusher through the rotor. Grinding to achieve autogenous crushing and high-density autogenous crushing can effectively improve the shape of finished sand particles and increase the efficiency of fine aggregate generation.

Advantages: high crushing efficiency, fine crushing and coarse grinding functions, strong material crushing ability; excellent product particle shape, low needle flake content, suitable for aggregate shaping, machine-made sand and high-grade highway aggregate production;

It is mainly used for machine-made sand processing of various ore materials such as basalt, river pebbles, river rocks, and granite. Under ideal conditions, the hourly output of this machine can reach 12-600t/h, which can easily meet the daily production needs of users of small and medium-sized planning enterprises. .

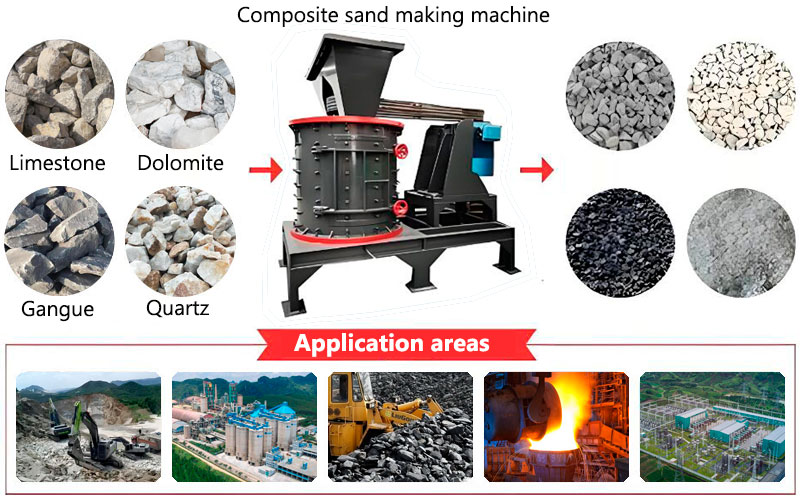

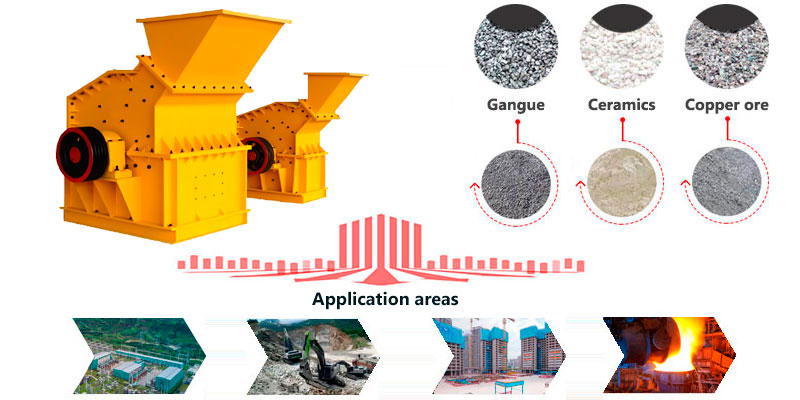

Compound sand making machine, also known as compound crusher, is a kind of small and medium-capacity sand making equipment. The material enters the crushing chamber from above. The high-speed rotating hammer impacts and crushes the ore and throws the stone to the lining plate. The stone and stone are , hammer head, lining plate and other multiple parties collide and rub to achieve the effect of crushing and making sand.

Because of its simple structure, small footprint, low investment cost, stable operation, and high quality sand production rate, it is widely used in many industries and fields such as mining, construction, roads, water conservancy, chemical industry, and environmental protection.

Due to its simple structure, easy operation, high crushing efficiency, and controllable particle size, the double-roller sand making machine can adapt to the crushing needs of different materials and different particle sizes by adjusting the roller gap and speed to meet the market's demand for high-quality sand.

It also has the characteristics of high efficiency, energy saving, and environmental protection, and is widely used in many industries and fields such as construction, chemical industry, metallurgy, and energy.

The fine crushing sand making machine is a third-generation sand making equipment. Driven by the motor, the rotor rotates at high speed. The material enters the crushing chamber for crushing through the plate hammer on the rotor, and then enters the second fine crushing chamber for crushing.

It has the characteristics of small discharge particle size, uniform particle shape, large production capacity, long hammer life, small supporting power, changing the third-level crushing into the second-level crushing, simplified process, simple structure, convenient maintenance, and stable operation. It is widely used in high-speed Highways, high-speed railways, high-rise buildings, hydropower station dam construction, concrete mixing stations and other industries and fields.

As an efficient and reliable crushing equipment, the hammer sand making machine uses a high-speed rotating hammer head to impact and shear the materials to achieve crushing and sand making effects.

Because it is economical, simple in structure and easy to maintain, it is suitable for soft or medium hard materials. It is widely used in many industries and fields such as mining, construction, transportation, water conservancy, and environmental protection.

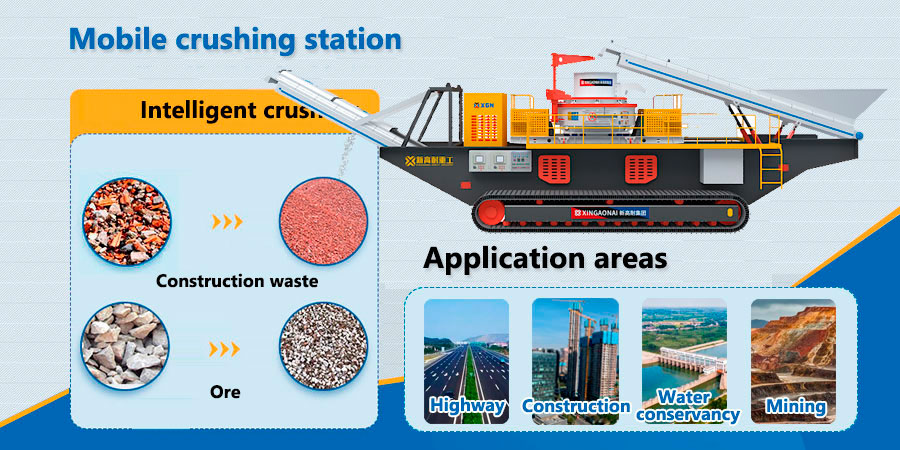

The mobile sand making machine is divided into three types: modular, tire and crawler. It is composed of a vibrating screen, a belt conveyor, a sand making machine, an electric motor and a control box. It is a crushing equipment that integrates sand making, crushing and screening. It has a high degree of efficiency. Mobility and flexibility, it can be quickly transferred to different working sites, saving time and transportation costs.

Because of its low energy consumption, strong mobility, high grinding efficiency, high screening accuracy, and intelligent operation, it is widely used in many industries and fields such as construction, roads, bridges, and water conservancy.

In general, each type of sand making equipment has its unique advantages and applicable scenarios. Users need to choose different types of sand making machines based on factors such as the hardness, humidity, content and particle size requirements of the required crushed materials. From the perspective of price, the quotations of different equipment and different models vary greatly. From a regulatory perspective, the larger the capacity and the larger the model, the more expensive the quotation will be. Users can choose the appropriate model of equipment based on their own investment costs. sand machine. If you have no experience and are unsure about your decision, you can also consult Xingaonai’s customer service staff online. The manufacturer will arrange one-on-one guidance from senior engineers and recommend suitable solutions for you based on the user’s finished product specifications, hourly output, site, budget, etc. model.

Superior: No content!

Abajo: No content!

Nuestros productos se han exportado a más de 170 países de África, Asia, América del Sur, Europa, etc. Estamos aquí para ofrecerle mejores productos y servicios.

Copyright © 2024-2030 Xingaonai Group Todos los derechos reservados. Sitemap