Xingaonai

Xingaonai

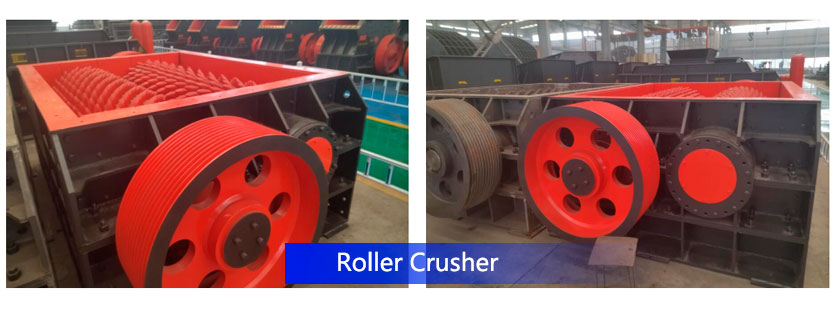

Roller crusher is a new type of mining crushing equipment. It has a simple, light and compact structure, which is convenient for medium and fine crushing operations. The output particle size is uniform, the crushing ratio is large, and the over-crushing is less. It is suitable for crushing stones below medium hardness. It adopts the extrusion crushing principle, with reasonable structure, powerful functions, high production capacity, and wide application range. It is widely used in mining, building materials, chemical and other industries. Xingaonai Heavy Industry will introduce the working principle and application field of roller crusher in detail.

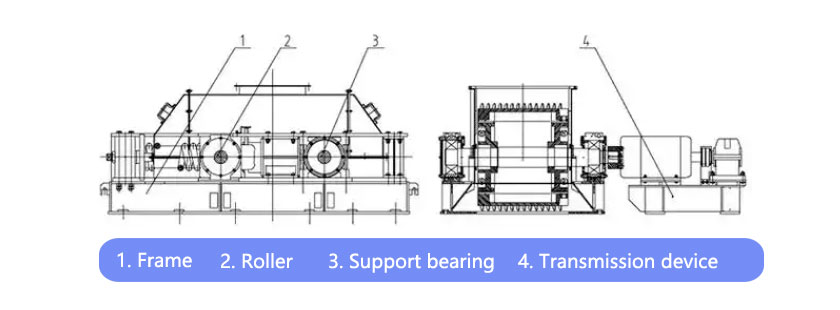

Frame, roller, transmission device, support bearing, adjustment device, etc. are the main components of roller crusher.

Frame: The supporting structure of roller crusher is frame, which is generally welded by steel plate, and roller and transmission device are installed on the frame.

Roller: The core component of roller crusher is roller, which is made of steel plate or cast iron. The diameter of roller can be customized according to the crushing requirements. The raised gear on the surface of roller is used to increase the friction between roller and stone to effectively improve the crushing effect.

Transmission device: usually composed of motor, coupling, reducer and other parts. The reducer drives the roller to rotate through the motor to realize the crushing operation.

Support bearing: mainly used to support the roller and perform rotary crushing operation under huge pressure.

The motor drives the roller to rotate through the transmission device, and the material is sent between the two rollers through the vibrating feeder. The two rollers squeeze and crush the material under the rotation movement, and the crushed material is discharged through the discharge port. If you encounter hard or unbreakable materials, the roller will automatically retreat through the hydraulic cylinder or spring device, and the gap between the two rollers will increase. At this time, the hard or unbreakable materials will be discharged naturally, which can effectively protect the machine from damage. At the same time, adjusting the distance between the two rollers can adjust the size of the crushed finished materials.

Advantages: The roller crusher has a simple structure, reasonable design, small space occupation, and adjustable particle size. And it is equipped with a protective device, which will automatically avoid hard objects and effectively increase the life of the roller crusher. Low noise, good sealing, less dust, small vibration, low environmental pollution during operation, and meets environmental protection standards.

Disadvantages: Roller crushers have high requirements for materials that are too wet, too viscous, and too large in size, which can easily affect the crushing effect.

According to the major advantages of roller crushers, they are widely used in the crushing industry of materials with medium hardness or below. In the mining industry, it is often used for coarse and medium crushing of raw ore; in the metallurgical industry, it is mainly used for crushing iron ore and manganese ore; in the chemical industry, it can be used for crushing raw materials such as fertilizers and chemicals, and plays a very important role in many industries.

In general, a good roller crusher can not only save you investment costs, but also improve production efficiency and reduce maintenance costs. Roller crushers have different manufacturers and models, and of course the prices will be quite different. Don't choose the cheapest or the most expensive, just choose the most suitable one to meet your needs.

Superior: No content!

Abajo: No content!

Nuestros productos se han exportado a más de 170 países de África, Asia, América del Sur, Europa, etc. Estamos aquí para ofrecerle mejores productos y servicios.

Copyright © 2024-2030 Xingaonai Group Todos los derechos reservados. Sitemap